Bosch Diesel took competitive tendering very seriously. All the considered systems were tested on one pilot project for half a year. After this deep testing, Easy Project was declared as the best solution. Other considered systems were Jira, MS Project, Wrike and Asana.

Implementation of Easy Project in Bosch Diesel

Implementation of Easy Project in Bosch Diesel was very complex. Bosch was able to clearly define all the project parameters, all of which were easily covered by Easy Project core and custom fields, and even custom fields were implemented.

While the initial stages were easy, certain problems started to arise during migration process from internal web system into Easy Project. Due to the fact that the internal web system offered no API or any other sort of integration, the only way to migrate data was through Excel. This way we were able to import all the projects with already defined parameters.

This issue was followed by a server issue, which arose from Bosch's security policies which hid all Bosch systems behind a firewall. Easy Project, on the other hand, runs on Linux server and it was impossible to install Linux and all necessary dependencies without at least access to common Linux repositories. Nevertheless, we were able to find an elegant solution - Bosche Deisel's Easy Project now runs in a docker, so the whole running environment is virtualized by docker and could be transferred to Bosch using a simple docker image.

Due to the fact that Easy Project was to be used by dozens of project managers, an onsite training was proposed instead of the usual remote training offered by Easy Project. Trainings were done in several sessions, separately for the head officers and for the project managers. Training was done in a workshop form as it was proven to be the most effective way of learning a new application. Visual presentations were intertwined with hands-on management of tasks in Easy Project. After an interactive workshop like this managers remembered more about the new application and were more willing to explore other features and start working on Easy Project right away.

Key benefits of Easy Project in Bosch Diesel

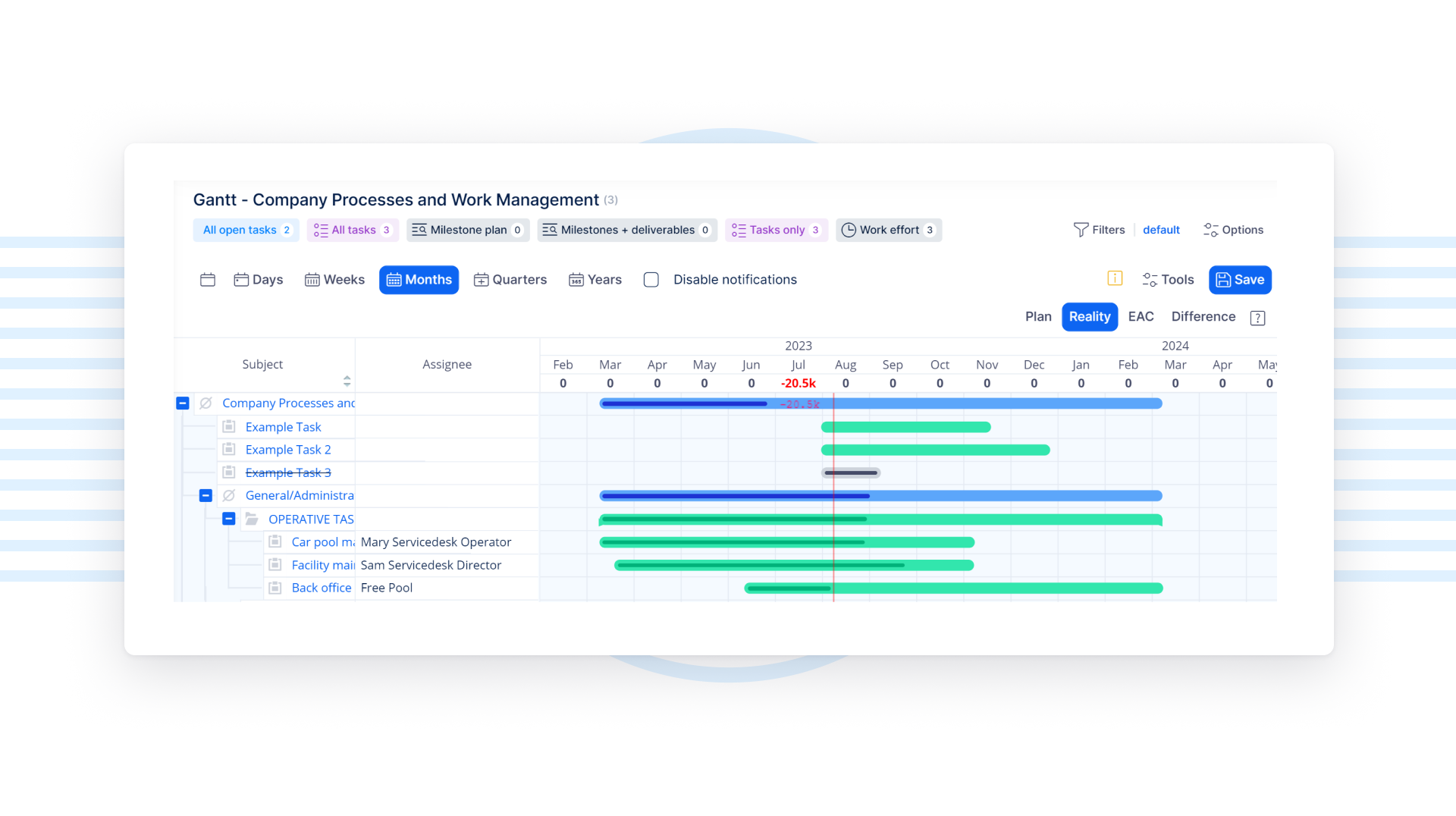

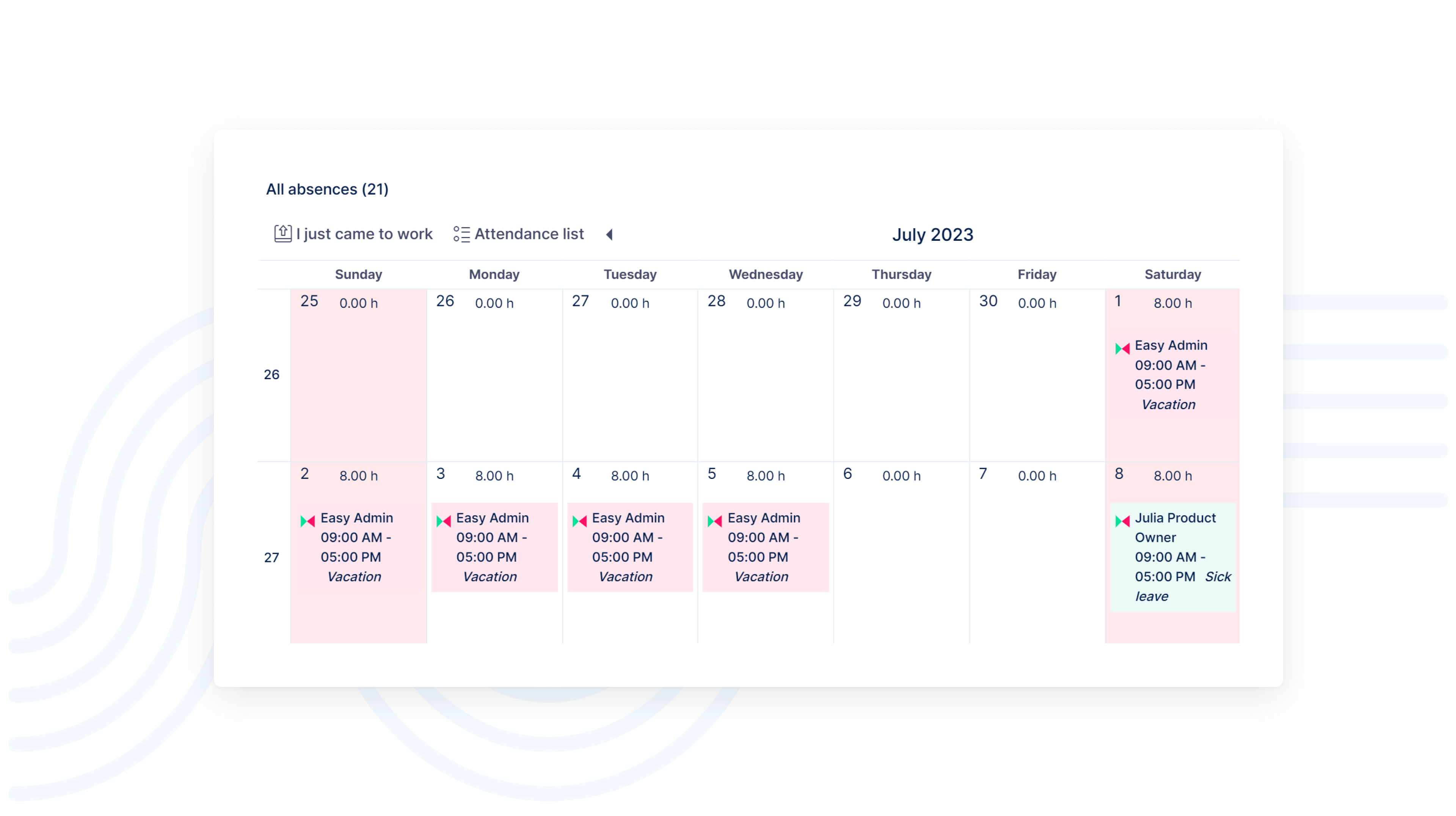

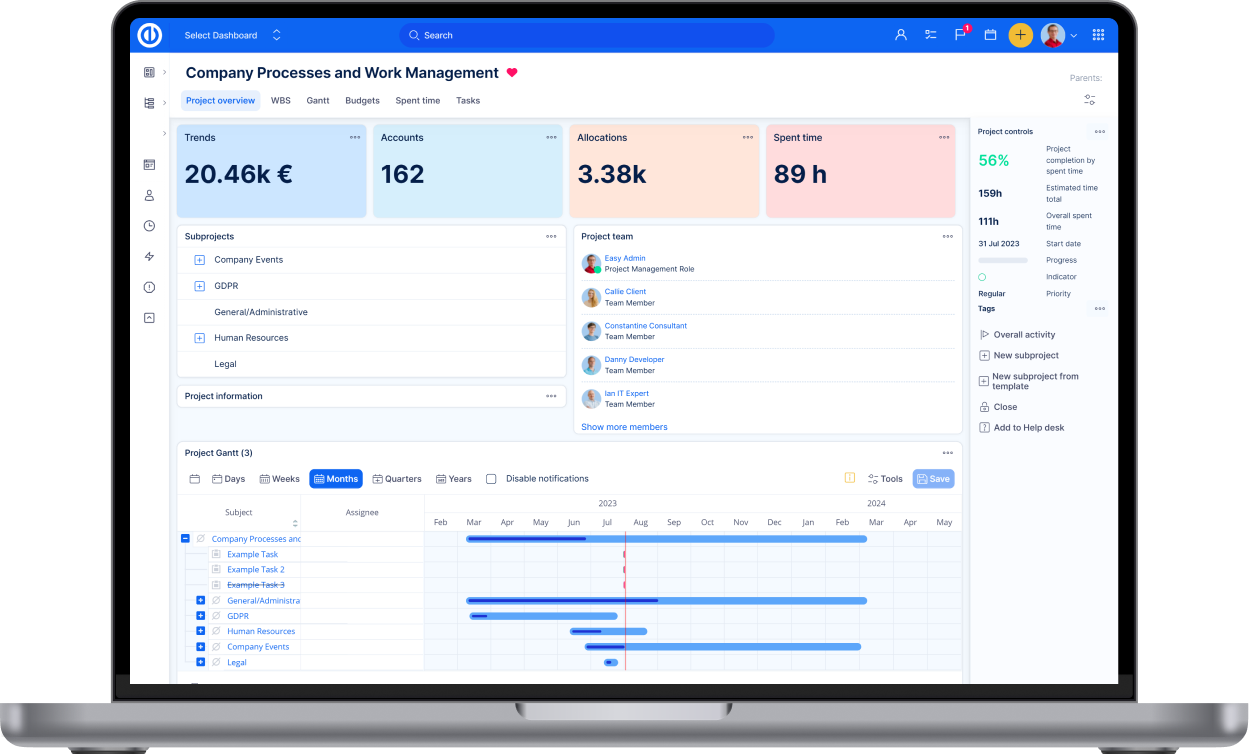

For a manufacturing company, the accuracy of production planning is very important. Due to the fact that production machines are THE most expensive asset for Bosch Diesel and all production companies in general, their full utilization is key to profitability. This planning need is fully met by the resource planning of Easy Project. Thanks to well-visualized resource management in Easy Project, Bosch Diesel is able to easily communicate the soonest and accurate delivery dates to their clients.

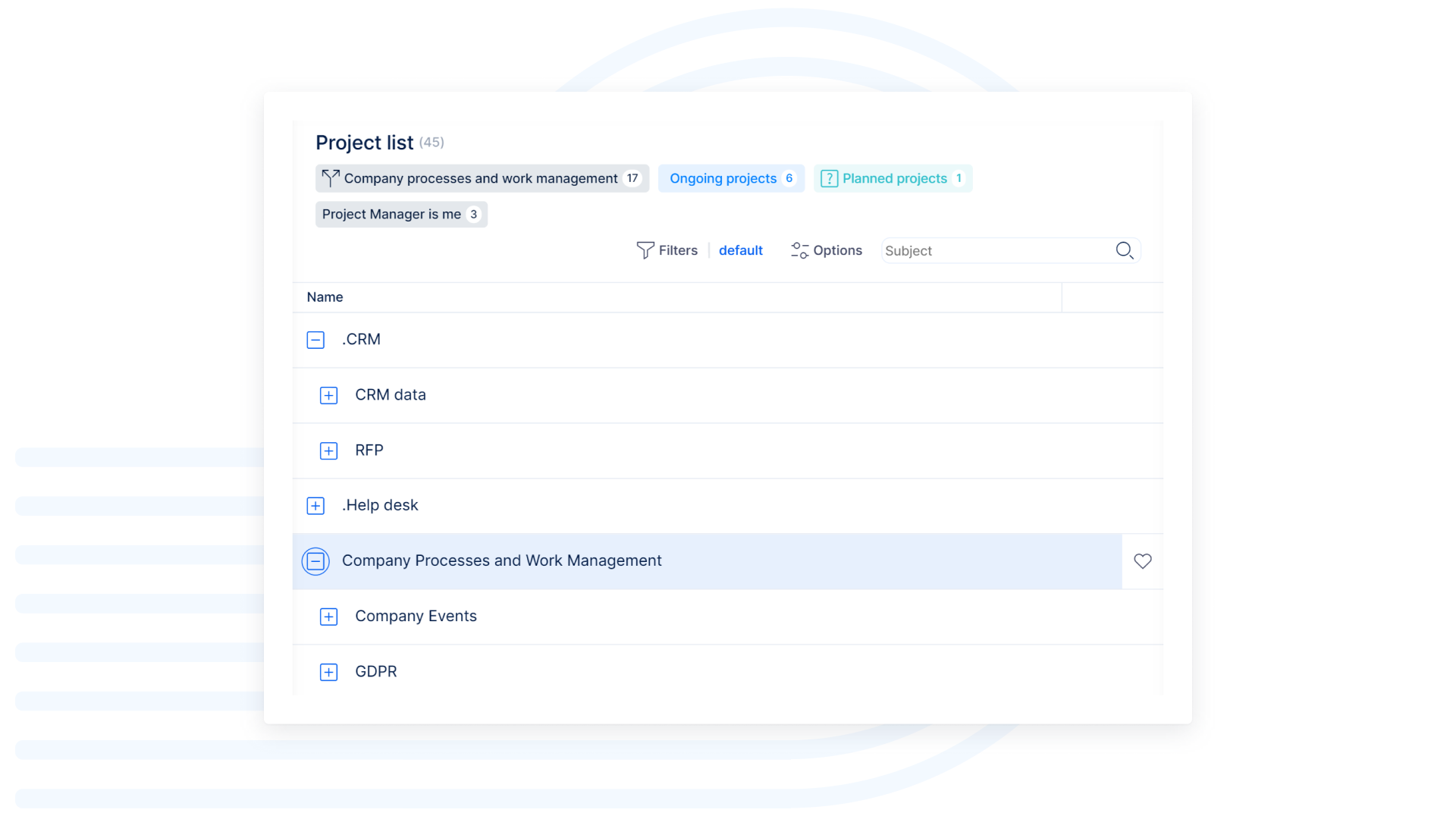

Another significant benefit brought to Bosch by Easy Project is project management efficiency. With Easy Project, managers are able to manage more projects simultaneously. Project management is now more intuitive, well visualized and more accurate. Easy Project eliminates any possibility of mistake from manual copying of information from one Excel sheet to another - a problem that often occurred at Bosche Diesel before. There are no more mistakes in planning caused by information that doesn't correspond to the reality. Elimination of these planning and management mistakes helped this production company increase profits and decrease costs.

In addition to that, Easy Project helps Bosche Diesel to enhanced teamwork and cooperation. Information flow was constantly stagnated due to use of Excel sheets, making it impossible to have information just-in-time and work as a team. In the environment where resource sharing is key to profitability, use of Excel sheets for the exchange of information simply didn't cut it. With Easy Project Bosch Diesel is able to share information immediately and are able to achieve synergies, where each manager as a member of a team is able to bring a greater value.